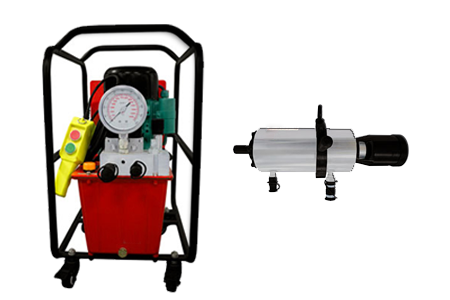

A tube bundle extractor ( tube bundle puller ) facilitates removing tube bundles from heat exchangers, boilers, or other process equipment. It grips and pulls tube bundle from its entire shell. Based on the tube bundle weight and its length, various extractors can be used.

Applications

Tube bundle pullers are widely used in industries where shell and tube heat exchangers are common, including:

- Petrochemical Plants: For maintenance of heat exchangers used in refining processes.

- Power Plants: In the maintenance of condensers and heat exchangers involved in power generation.

- Chemical Plants: For various process heat exchangers.

Operation

Using a Tube bundle puller typically involves the following steps:

- Preparation: Ensuring the heat exchanger is properly shut down and depressurized.

- Attachment: Securing the extractor to the tube bundle and the heat exchanger shell.

- Extraction: Using the tube bundle puller to carefully pull the bundle out of the shell.

- Maintenance: Performing the necessary cleaning, inspection, and repair work on the bundle.

- Reinsertion: Using the tube bundle puller to carefully reinsert the bundle into the shell.

Tube bundle pullers are critical tools for maintaining the efficiency and reliability of heat exchangers, ensuring that industrial processes run smoothly and safely.

Key features of Tube Bundle Extractor

- Reducing overhaul time

- User friendly

- Compatible for different heat exchangers

- Enhanced safety

- Affordable

Reviews

There are no reviews yet.